PEEK Check Valves - HPLC & Life-Science

Description

PEEK (polyetheretherketone) check valves are essential components in high performance liquid chromatography (HPLC) systems as well as life science applications. They are characterized by their excellent chemical resistance, mechanical strength and ability to withstand extreme pressure conditions. These valves provide unidirectional fluid flow, maintaining system pressure and preventing backflow, which is critical for accuracy in analytical and bioanalytical processes. Depending on the requirement of the system, PEEK check valves are available in various styles including diaphragm valves, ruby ball valves with and without spring and duckbill valves.

Types of PEEK Check Valves for HPLC

PEEK Check Valves with Diaphragm

PEEK diaphragm check valves are designed with a chemically resistant FFKM diaphragm that opens to allow unidirectional fluid flow and closes to prevent backflow. These valves are ideal for use in life science applications where contamination minimization and sterile, unidirectional flow are required.

Advantages:

- High chemical resistance to a wide range of solvents and reagents.

- Sterile design suitable for life science applications such as protein analysis and bioanalytics.

- Suitable for pressures up to 130 bar, making them ideal for high pressure applications.

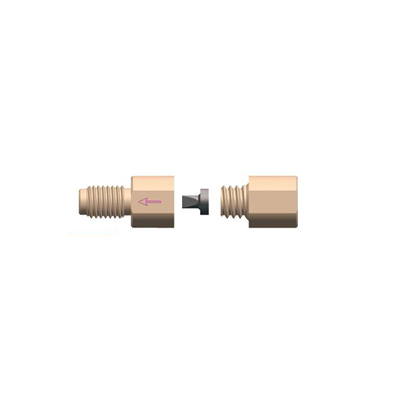

PEEK Check Valves with Ruby Ball and Spring

In this configuration, the valve uses a ruby ball as the sealing element, combined with a spring mechanism that enhances the valve’s responsiveness to pressure changes. The ruby ball is extremely durable and wear-resistant, ensuring a reliable seal over extended use. The spring ensures quick closure, which is particularly important in high-pressure HPLC systems where backflow must be prevented immediately after pressure release.

Key Features:

- Precision sealing: The hardness of the ruby ball ensures long-term durability.

- Rapid response: The spring ensures the valve closes quickly and securely.

- Suitable for high-pressure applications, up to 700 bar.

- Resistant to aggressive chemicals, including acids, bases, and solvents commonly used in both HPLC and life science applications.

PEEK Check Valves with Ruby Ball (Without Spring)

This design features a ruby ball for sealing, but without a spring. The flow itself, under system pressure, opens and closes the valve. This springless design minimizes the complexity of the valve while still offering high durability and chemical resistance. It is especially suitable for systems where the flow rate is more stable and pressure fluctuations are minimal.

Advantages:

- Simplified design with fewer moving parts, reducing the risk of mechanical failure.

- High wear resistance, thanks to the ruby ball’s durability.

- Ideal for medium to high-pressure systems, up to 700 bar.

- Excellent for chemically harsh environments where long-term reliability is required.

PEEK Duckbill Check Valves

Duckbill check valves are elastomeric components that are molded into a “duckbill” shape, allowing fluid to flow in only one direction while preventing backflow. For FKM-based duckbill valves, the material offers excellent chemical resistance, and the duckbill design ensures reliable sealing under different pressure conditions. These valves are suitable for medium pressure operated applications and offer flexibility, particularly when handling fluids with particles or varying viscosities.

Key Benefits:

- Self-sealing design: The duckbill shape naturally seals without the need for additional components.

- Flexibility in pressure handling, making them ideal for systems with dynamic pressure changes.

- Chemically inert, compatible with a wide range of solvents and bioanalytical fluids.

- Capable of handling pressures up to 30 bar, depending on the application.

Applications in HPLC and Life Sciences

PEEK check valves are commonly used in HPLC systems for controlling solvent flow, maintaining pump pressure, and preventing contamination. In life sciences, these valves are essential in processes requiring sterile, precise fluid handling, such as in pharmaceutical production, protein purification, and bioprocessing. The diverse configurations of PEEK check valves allow them to be tailored to specific needs, whether it’s high-precision flow control, handling aggressive chemicals, or withstanding the high pressures demanded by advanced analytical equipment.